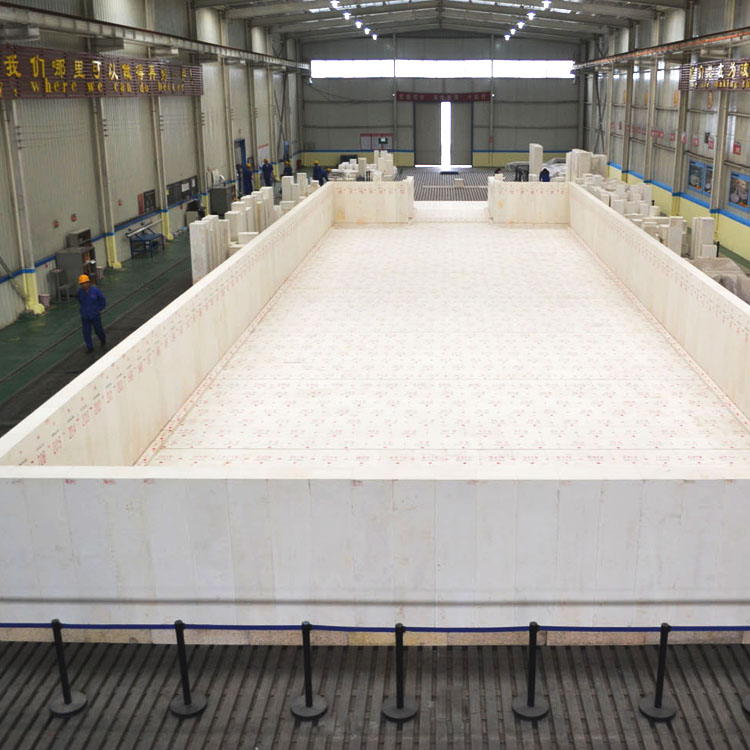

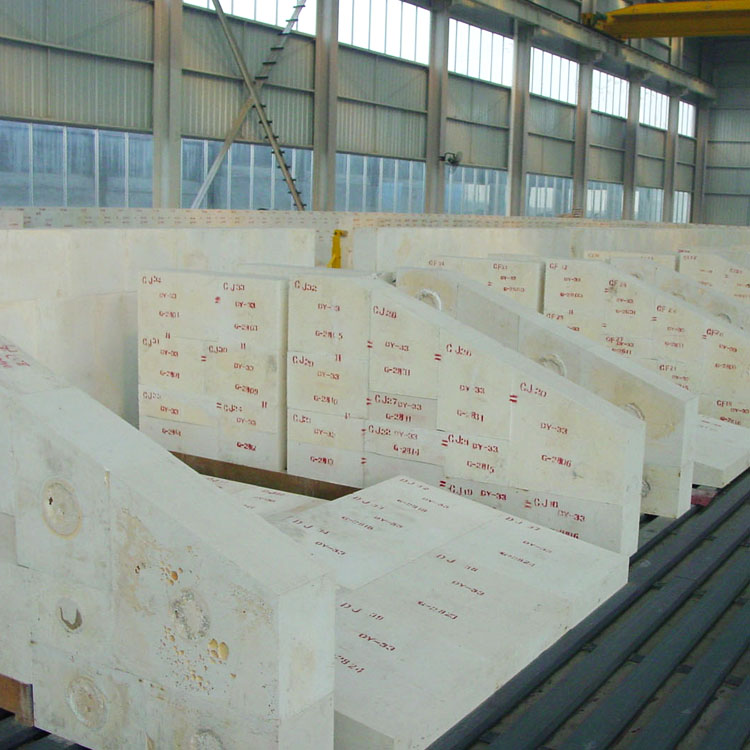

Fused AZS TY-AZS36D is a refractory material produced using the electric fusion casting process, by melting the mixture in an electric furnace and molding it in a liquid state. Compared with the traditional AZS36 process, TY-AZS36D further reduces its Na2O content through the oxidation process and improves the quality of the glass phase. Therefore, its corrosion resistance and anti-crystallization ability are significantly improved, and it is suitable for glass contact areas, such as floats. French glass kiln, bottle kiln side walls, floor tiles, dog room and other parts. TY-AZS series blocks have passed ISO international certification. They use high-purity raw materials, scientific formulas, and advanced technology. They are produced under the guidance of a professional team. They have more than 30 years of production and market experience, and have established a stable customer base in overseas markets and maintained a long-term cooperate. Customers who need refractory materials for high-temperature furnaces will never be disappointed if they choose us. Typical technical indicators of TY-AZS36D include: Al2O3 content ≥50.00%, ZrO2 content ≥35.50%, SiO2 content ≤12%, Na2O+K2O content ≤1.35%; bulk density ≥3.93 g/cm³, apparent porosity ≤2.0%, Cold compressive strength ≥300 MPa, glass phase precipitation temperature ≥1400°C, etc.

1. The electrofusion casting process is used to improve the quality of the glass phase and significantly improve the corrosion resistance and crystallization resistance.

2. The Na2O content is further reduced through the oxidation process and the service life is extended.

3. High-purity raw materials and scientific formulas, coupled with more than 30 years of production and market experience, ensure product reliability.

4. It has passed ISO international certification to ensure that the quality meets international standards.

5. Using advanced technology and guided by a professional team in production, we provide stable and high-performance refractory materials.

6. Bulk density ≥3.93 g/cm³, apparent porosity ≤2.0%, cold compressive strength ≥300 MPa, reflecting excellent physical properties.

1. Suitable for glass contact areas, such as float glass furnaces, bottle furnace side walls, floor tiles, dog rooms, etc.

2. Customers who need refractory materials for high temperature furnaces are our ideal service targets.