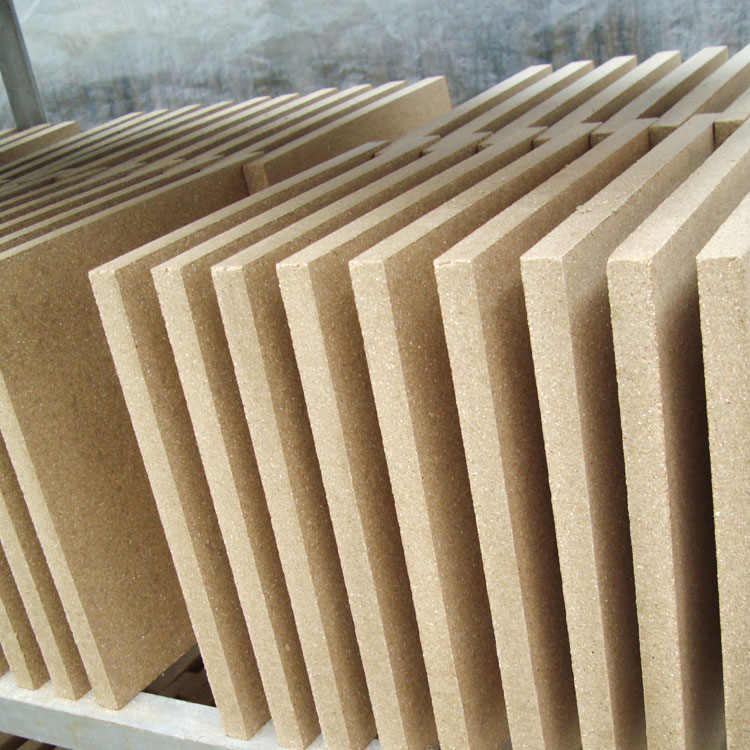

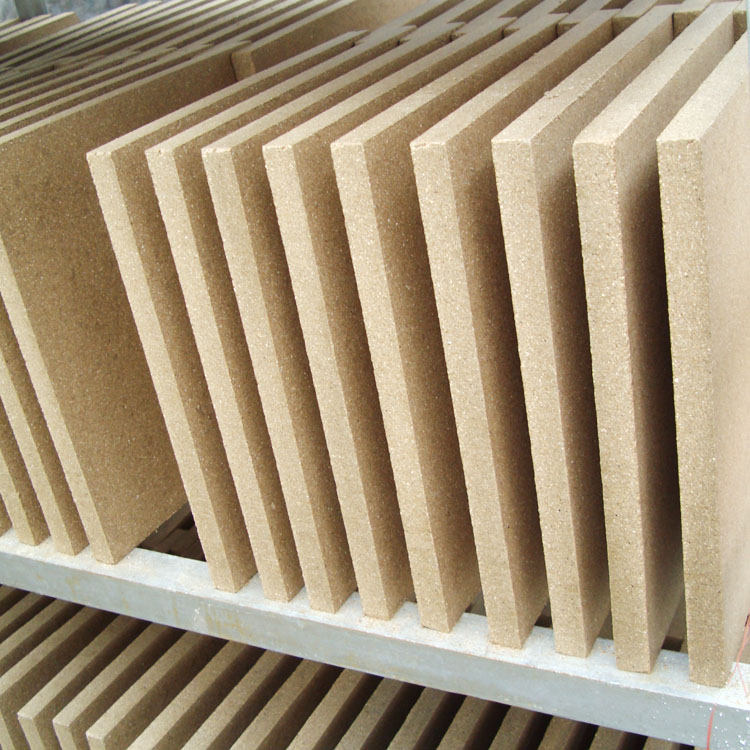

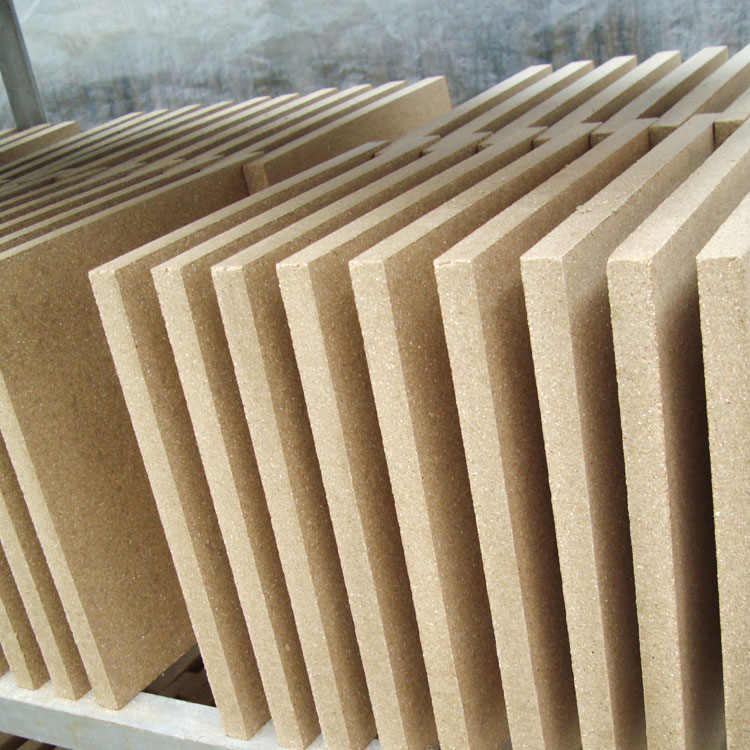

Vermiculite insulation board is a high-performance insulation material specially developed for the aluminum industry, especially electrolytic aluminum tanks. Its main raw material is vermiculite and can be used at operating temperatures up to 1050°C. In a high-temperature environment, organic impurities in the vermiculite plates will be removed, thereby achieving a purification effect. During use, the strength of the vermiculite insulation board will increase, the thermal conductivity will decrease, and the overall quality will be significantly improved. Due to these characteristics, the service life of the aluminum tank can be extended to more than 10 years, significantly reducing the maintenance cost of the electrolytic aluminum tank. At the same time, the low thermal conductivity can effectively reduce the heat loss of the aluminum tank and achieve power and energy saving effects. Thanks to its formulation and processing techniques, vermiculite refractory insulation panels are effectively resistant to attack by fluoride and cryolite and will not be wetted by molten aluminum.

1. Working temperature up to 1050℃, suitable for high temperature environment.

2. The strength increases and the thermal conductivity decreases, significantly improving the overall quality.

3. It can greatly extend the service life of aluminum troughs to more than 10 years and reduce maintenance costs.

4. Low thermal conductivity effectively reduces the heat loss of aluminum troughs and achieves power and energy saving.

5. Resistant to corrosion by fluoride and cryolite, and not wetted by molten aluminum.

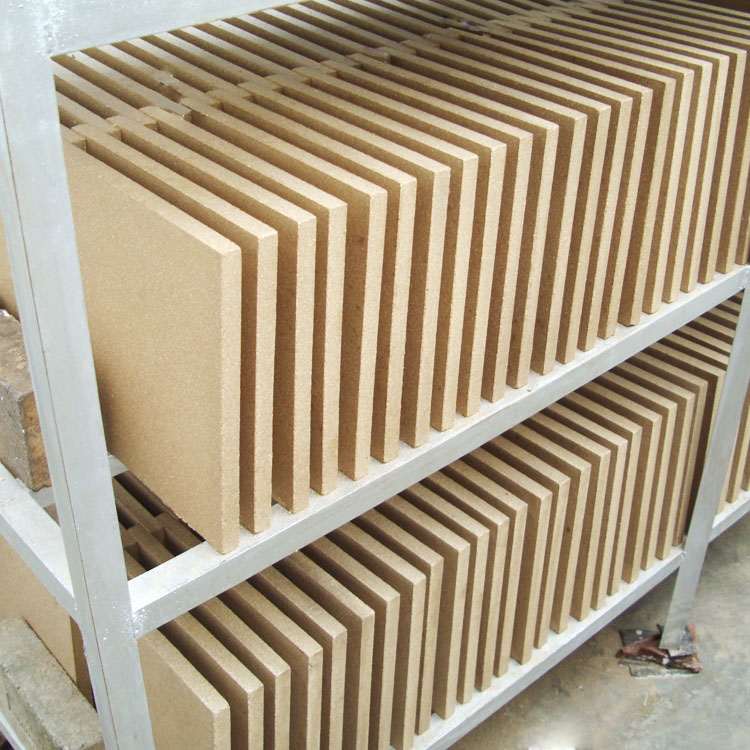

1. Backing insulation board or surface insulation board of electrolytic aluminum cell.

2. Secondary aluminum industry, such as furnace walls, chutes or furnace roof backing plates to maintain furnace.