Silicon nitride combined with silicon carbide brick is a high-quality refractory material, mainly used in non-ferrous mining, metallurgical blast furnaces and ceramic industries. This type of brick has the characteristics of high strength, good thermal conductivity, good thermal shock resistance, strong corrosion resistance, etc. The main performance has been tested and evaluated by independent testing laboratories, and the effect is good. At present, the product has been recognized by more than ten large foreign companies, and more than 80% of the output is supplied to more than ten countries and regions, especially Europe and the United States. At the same time, the product is also supplied to many large domestic non-ferrous metallurgical companies.

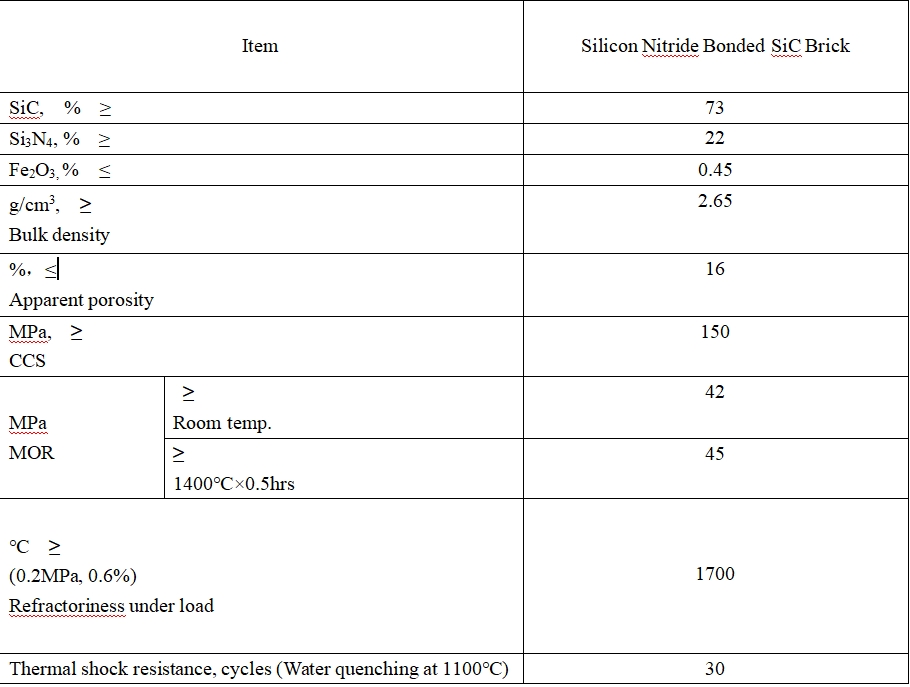

1. It has ultra-high strength and can withstand extreme industrial environments, with an apparent porosity of no more than 16%.

2. Excellent thermal conductivity and thermal shock stability

3. Strong corrosion resistance, suitable for various harsh working conditions.

4. The load softening temperature is not less than 1700℃, ensuring stable operation under high temperature.

5. Cold flexural strength is as high as 42 MPa (room temperature) and 45 MPa (1400℃×0.5 hours).

1. Mainly used for aluminum electrolytic cell side wall lining, aluminum refining furnace burner, garbage incinerator, etc.

2. Mainly used for the lower part of blast furnace body, furnace belly, furnace belly, boiling furnace boiler lining, etc.

3. Mainly used for kiln furniture such as furnace linings and furnace columns in the ceramic, electrical porcelain, grinding wheel and other industries.

4. Mainly used for high temperature kiln heat exchange tubes, aluminum refining furnace heaters, blast furnace tuyere sleeves, etc.