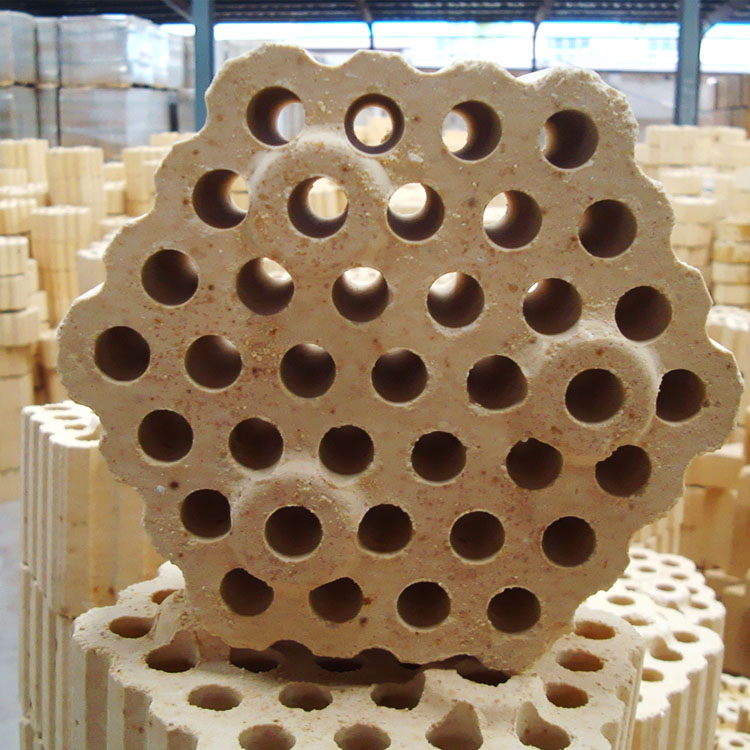

Silica bricks for hot blast furnaces are used in the high-temperature parts of blast furnaces. They are a type of siliceous refractory product with flaky quartz as the main phase. Due to the increase in wind temperature, the clay bricks or high-alumina bricks previously used in the high-temperature parts of hot blast furnaces have been gradually replaced by silica bricks and low creep high-alumina bricks.

1. High purity: SiO2 content ≥95%, ensuring stable high temperature performance.

2. Excellent thermal conductivity: Good thermal conductivity can support the efficient operation of the hot air furnace.

3. High temperature pressure resistance: cold pressure strength ≥45MPa, able to withstand harsh working environment.

4. Low expansion rate: thermal expansion rate (1000℃) ≤1.25%, ensuring structural stability.

5. High load softening point: 0.2MPa load softening temperature ≥1650℃, suitable for high temperature environment.

6. Low creep rate: 1550℃ creep rate is 0.8% (0.2MPa×50 hours), reliable for long-term use.

1. The high temperature area of the hot air furnace grid room.

2. Other industrial furnace equipment under high temperature and high pressure conditions.