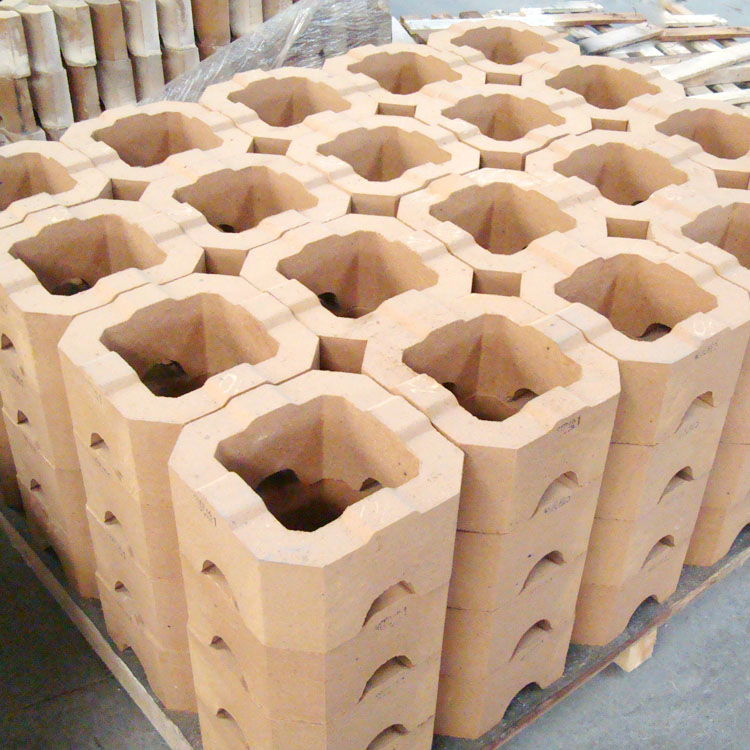

Fused magnesia brick is a high-performance refractory brick, which is mainly made of molten magnesium as the main raw material, through reasonable particle size ratio, high pressure molding and high temperature sintering. It has excellent resistance to basic slag, high refractoriness, thermal stability, erosion resistance and spalling resistance. This refractory brick shows excellent compression, bending strength and wear resistance at high temperature, and can effectively resist the erosion of alkaline residues. Its high fire resistance also includes excellent thermal shock resistance and spalling resistance, ensuring stability and durability in high temperature operation.

1. Excellent basic slag resistance: effectively resist alkaline residue erosion and extend equipment life.

2. Excellent fire resistance: It exhibits excellent compressive and bending strength in high-temperature operating environments.

3. Strong thermal stability: ensure stability and durability under high temperatures and reduce replacement frequency.

4. High corrosion resistance: significantly improve the service life of glass furnaces and other equipment.

5. Excellent wear resistance: effectively prevent wear and loss under high temperature conditions and extend the service life.

6. Excellent thermal shock resistance: ensuring stable performance even under severe temperature changes.

7. Strong peeling resistance: maintain integrity during high-temperature operations and reduce the risk of chipping.

1. Mainly used in the regenerator of glass furnace, providing efficient refractory solutions.

2. The upper structure of high temperature glass furnace prolongs the equipment life by enhancing the structural stability.