Magnesia-zirconium bricks are composed of fused magnesia sand and zircon sand and are alkaline refractory materials. The product has high density (bulk density greater than 3.08g/cm³) and can resist erosion by alkaline atmosphere and alkaline slag, so it is widely used in glass kilns, regenerators, cement kilns, steel electric furnaces and non-ferrous metal metallurgy. The main characteristics of magnesia-zirconium bricks include alkali resistance, slag corrosion resistance, spalling resistance and high temperature tolerance.

1. High-density material: Volume density greater than 3.08g/cm³, providing excellent structural strength and durability.

2. Excellent alkali resistance: can effectively resist erosion by alkaline atmosphere and alkaline slag, and prolong service life.

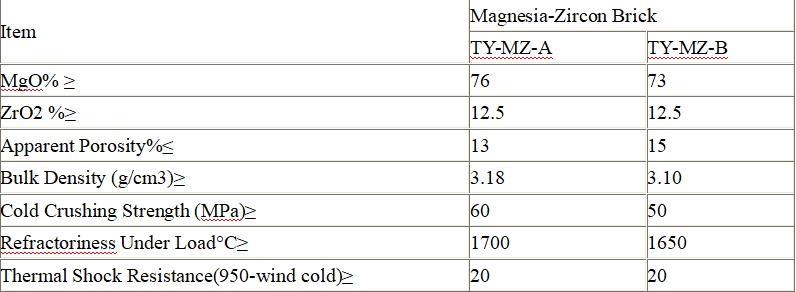

3. High compressive strength: The cold compressive strength of TY-MZ-A model is ≥60MPa, ensuring stability in harsh environments.

4. Strong high temperature tolerance: load softening temperature ≥1700°C, suitable for high temperature operations.

5. Excellent thermal shock resistance: thermal shock stability (950°C air cooling) ≥ 20 times, preventing the material from cracking under rapid cooling and heating conditions.

1. Glass kilns and regenerators: refractory materials in high temperature working environments.

2. Cement kiln: An industrial kiln that requires high temperature resistance and corrosion resistance.

3. Steel electric furnace and non-ferrous metal metallurgy: refractory brick materials under harsh working conditions.