Magnesia chrome brick is a high-performance refractory material made of sintered magnesia and refractory grade chromium ore as the main raw materials, and uses silicate to bind the gaps between refractory particles. This product has the following salient features: high strength, corrosion resistance, erosion resistance, excellent slag resistance and good thermal shock stability. Its refractoriness exceeds 2000°C, its load softening temperature is above 1550°C, and its volume stability in high temperature environments is good. Compared with magnesia bricks, its performance in hot and cold cycle environments is superior.

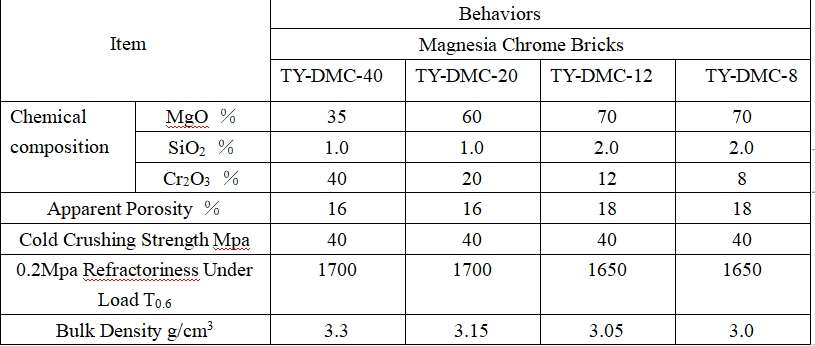

1. High strength: Magnesia-chrome bricks have extremely high mechanical strength, and the compressive strength at room temperature reaches 40MPa, ensuring the stability of the brick body.

2. Excellent corrosion resistance: It has excellent corrosion resistance and performs well in high temperature and corrosive environments.

3. High temperature stability: Its refractoriness exceeds 2000℃, and its softening temperature under load is between 1650℃ and 1700℃, making it suitable for harsh high temperature environments.

4. Thermal shock stability: Magnesia-chrome bricks perform well in hot and cold cycle environments, effectively preventing cracking and falling off.

1. Metallurgical industry: suitable for the lining and top of blast furnace, converter and electric furnace.

2. Power industry: suitable for lining materials of high-temperature boilers and combustion chambers.

3. Building materials industry: Suitable for equipment that requires high temperature operation, such as cement kilns and lime kilns.