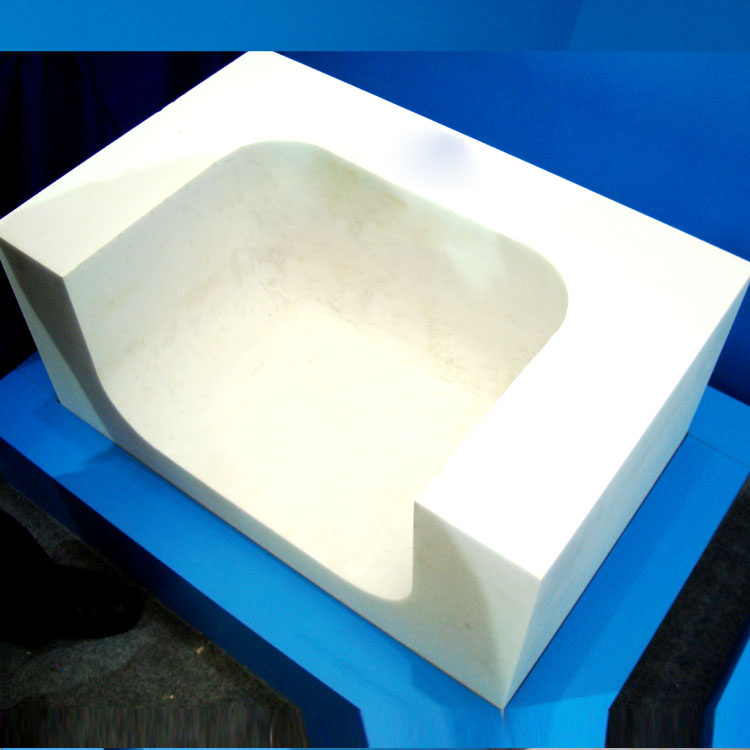

The fused α-alumina block TY-A is a refractory material made by melting and casting high-purity alumina with an Al2O3 content of more than 98% in an electric furnace at 2000°C. Due to the dense structure directly formed during its production process, this block has excellent resistance to strong alkalis. At a high temperature of 1350°C, it shows extremely strong corrosion resistance and hardly contaminates the molten glass. Since it does not contain impurities such as Fe2O3 and TiO2, it rarely generates bubbles when in contact with the molten glass, thereby minimizing the contamination of the molten glass.

1. The Al2O3 content exceeds 98%, and it is formed in a 2000°C electric furnace, with excellent resistance to strong alkali and corrosion.

2. It exhibits extremely strong corrosion resistance at high temperatures of 1350°C and hardly contaminates the molten glass.

3. It does not contain impurities such as Fe2O3 and TiO2, and rarely produces bubbles when in contact with molten glass, thus minimizing the contamination of the molten glass.

4. High density and superior thermal stability make it an ideal material for the low temperature zone of glass melting furnaces and metallurgical titanium furnaces.

1. Applicable to the low temperature area of glass melting furnace to ensure the purity of molten glass.

2. Suitable for metallurgical titanium furnace, providing excellent thermal stability and corrosion resistance.