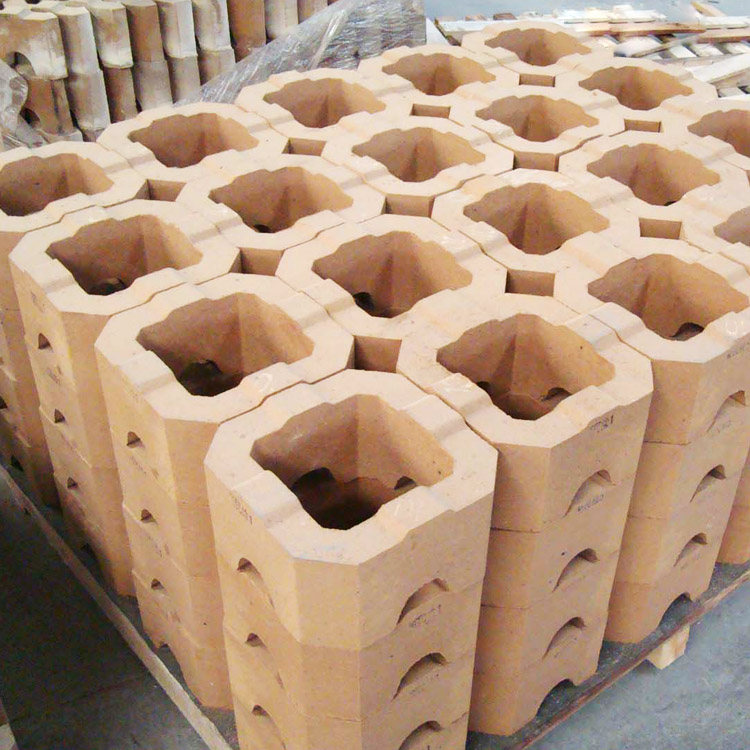

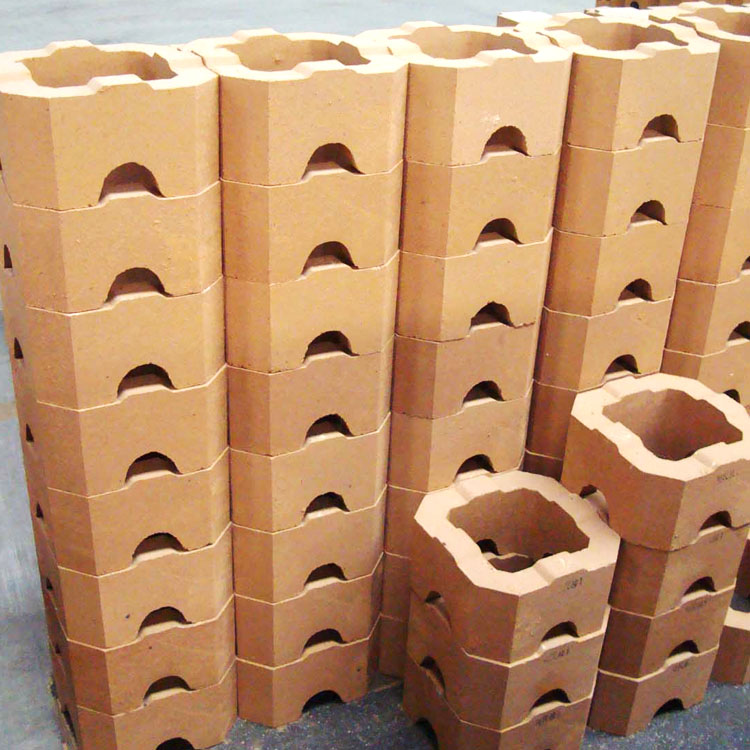

Magnesia brick is a basic refractory material mainly composed of periclase phase, with excellent high temperature performance and erosion resistance. Its characteristics include good basic slag resistance, high refractoriness, thermal stability, erosion resistance and spalling resistance. Magnesia brick shows excellent pressure resistance, wear resistance, high temperature sintering performance, erosion resistance, thermal shock resistance and spalling resistance in high temperature environment. In addition, it also has high refractory load, excellent mechanical strength and resistance to alkali residue erosion. Due to these excellent properties, magnesia brick is widely used in regenerators of glass kilns and other high temperature furnaces, which can effectively resist high temperature corrosion and erosion.

1. Excellent high temperature stability: Magnesia bricks exhibit excellent pressure and wear resistance at high temperatures and are suitable for harsh industrial environments.

2. Anti-erosion and anti-stripping: It has excellent anti-erosion and anti-stripping capabilities and can effectively resist high-temperature corrosion.

3. Excellent mechanical strength: The compressive strength at room temperature is not less than 60Mpa, ensuring durability for long-term use.

4. Alkali residue resistance: It has high refractory load and good resistance to alkali residue erosion, suitable for alkaline environment.

5. Thermal stability: 100℃ water cooling cycle thermal shock stability is up to more than 18 times, ensuring stable performance at high temperatures.

1. Glass kiln regenerator: especially suitable for the regenerator part in high temperature glass kiln.

2. High temperature furnaces and kilns: widely used in various high temperature furnaces and kilns, with outstanding refractory performance.