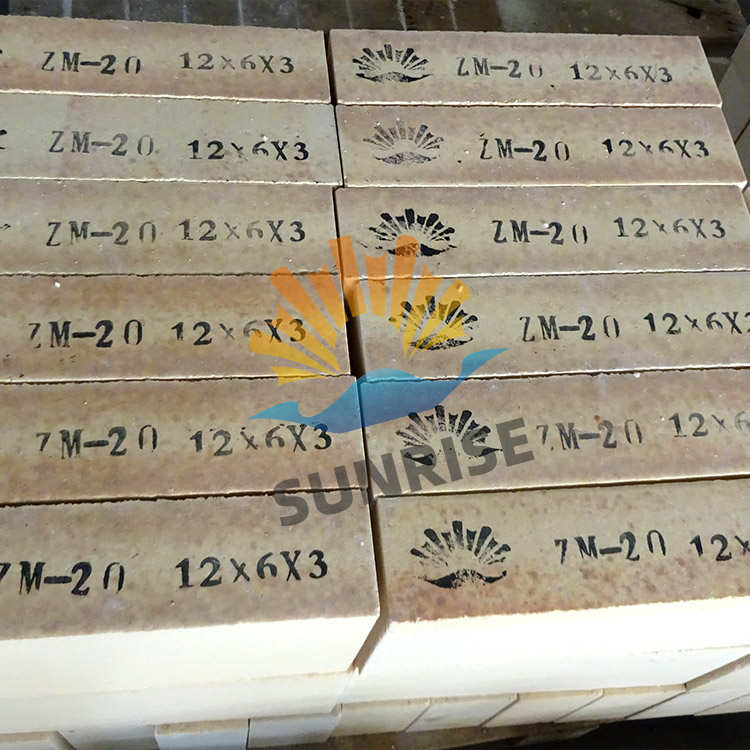

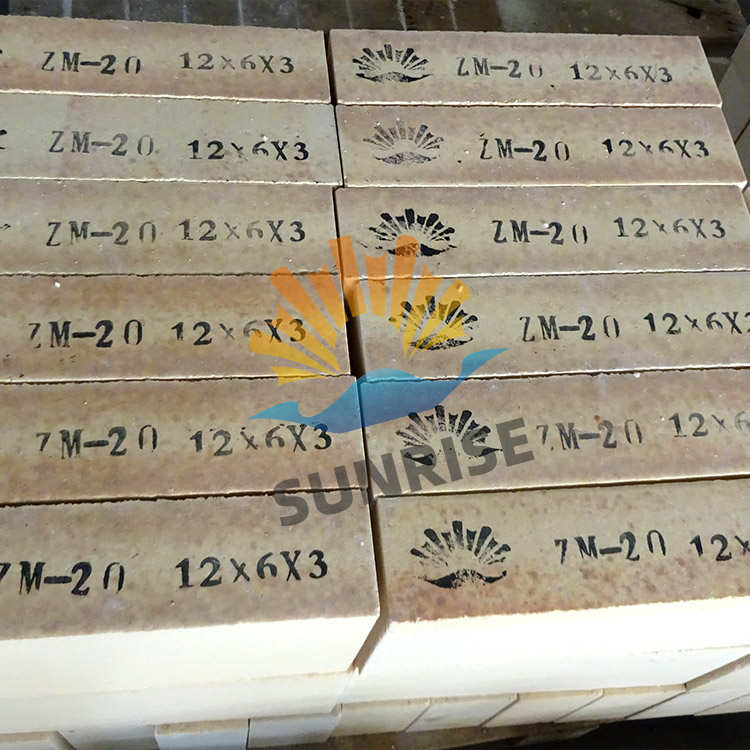

In today's fast-paced glass manufacturing industry, the need for materials that can withstand extreme conditions is more crucial than ever. Zircon mullite bricks have emerged as a superior solution, providing unique properties that cater to the specific demands of modern glass production.

Zircon mullite bricks are renowned for their high thermal stability and low thermal expansion. This combination ensures that these bricks can endure the thermal shocks experienced during glass manufacturing without cracking or deforming. Furthermore, their excellent resistance to corrosion makes them ideal for use in environments where other materials might fail.

1. Durability: The longevity of zircon mullite bricks reduces the frequency of replacements, ultimately lowering operational costs.

2. Thermal Efficiency: Their thermal efficiency promotes energy savings, enhancing the overall sustainability of glass production processes.

3. Versatility: These bricks can be used in a variety of applications, making them a flexible choice for different glass production methods.

In conclusion, zircon mullite bricks represent an optimal choice for modern glass manufacturing. Their unique properties not only enhance production efficiency but also contribute to the sustainability of the manufacturing process. By investing in zircon mullite bricks, manufacturers can secure a competitive advantage in the ever-evolving glass industry.