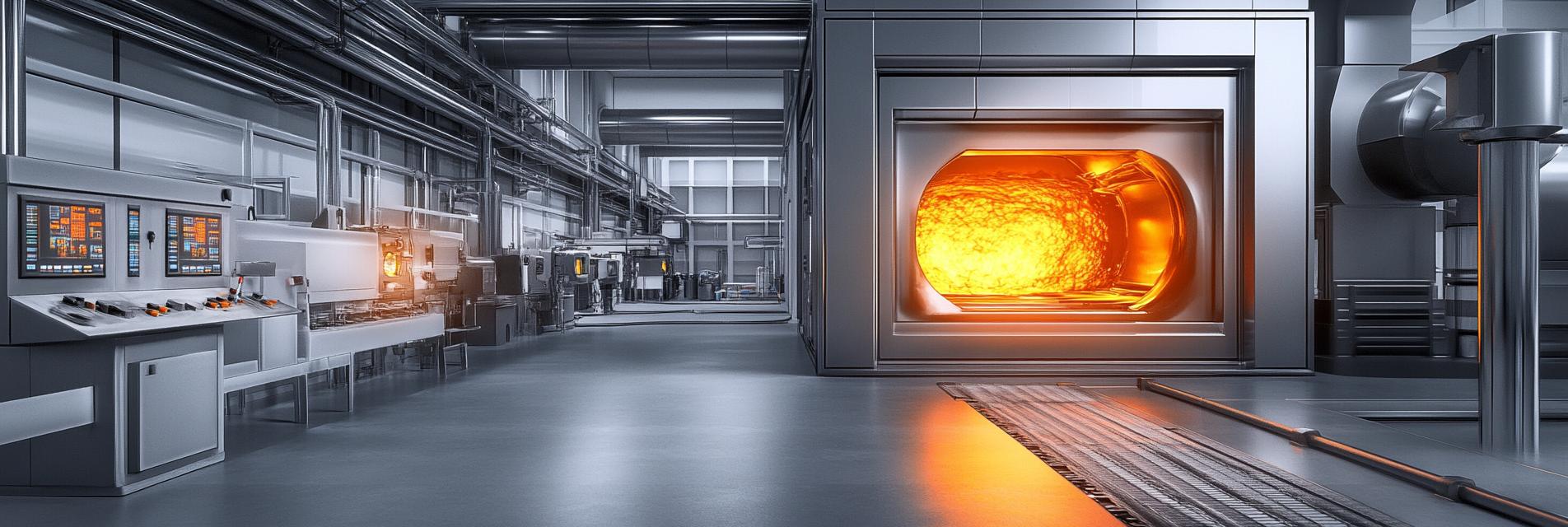

High-temperature kilns play a crucial role in various industrial applications, particularly in the manufacturing of ceramics, metals, and glass. As a leader in marketing strategies, I recognize the essential functions of these kilns, which are designed to withstand extreme thermal conditions while delivering consistent and high-quality results.

The construction of high-temperature kilns is engineered to support the demands of high-temperature processes. These kilns are typically built using refractory materials that not only resist thermal shock but also maintain integrity under extreme conditions. The efficiency of a kiln relies heavily on its insulation properties, heat-up times, and the ability to maintain uniform temperatures throughout the firing process.

High-temperature kilns find applications across several industries, with the ceramic industry being a prominent example. In ceramics, kilns are essential for firing clay bodies and glazes, ensuring durability and aesthetic qualities. Furthermore, in metallurgical processes, kilns are used for sintering and melting metals, allowing manufacturers to create advanced components with specific material properties. Glass production also relies on these kilns to reach the necessary temperatures for melting raw materials and forming glass products.

The advantages of using high-temperature kilns are manifold. Firstly, they enhance production efficiency by providing faster heating and cooling cycles which lead to improved productivity. Secondly, the consistent temperature control facilitates higher quality output, minimizing variations that can affect product integrity. Lastly, the flexibility in design allows these kilns to accommodate various loads, making them suitable for both small-scale and large-scale operations.

In conclusion, understanding the significance and functionality of high-temperature kilns is critical for industries that depend on precise thermal processing. As a leader in marketing and operations, promoting the benefits of these kilns can significantly aid in achieving sustainable growth and competitive advantages in the respective markets. Therefore, investing in high-temperature kilns translates to better products and enhanced operational efficiency.