As the leader in marketing for refractory materials, I often focus on the unique performance characteristics of zircon mullite bricks. These bricks have become increasingly significant within the glass industry, not only due to their remarkable thermal properties but also their ability to enhance production efficiency. In this article, I will share insights about their advantages and various applications, which are crucial for industry stakeholders.

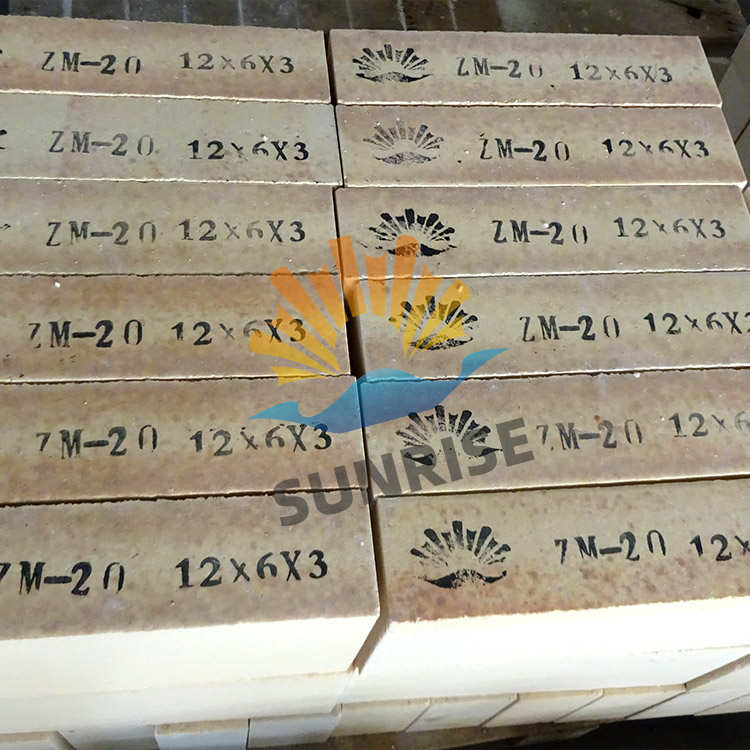

Zircon mullite bricks are recognized for their superior thermal stability and excellent mechanical strength. They exhibit a remarkable resistance to thermal shock and chemical corrosion, making them ideal for extreme conditions found in glass manufacturing. The low thermal conductivity of these bricks ensures efficient heat retention during the firing process, which is essential for optimal glass quality.

The applications of zircon mullite bricks in the glass industry are vast. They are commonly used in kiln linings, which require materials that can withstand high temperatures and are chemically inert. Additionally, these bricks serve as structures in melting units, helping to improve energy efficiency. Their versatility allows for integration in various production processes, including float glass and container glass manufacturing, demonstrating their pivotal role in enhancing operational capabilities.

Implementing zircon mullite bricks can result in significant operational advantages. Not only do they extend the service life of furnaces, but they also minimize maintenance costs. Their efficiency reduces energy consumption, which is crucial in today’s environmentally conscious market. As manufacturers strive for sustainability, this material emerges as the preferred choice, aligning performance with environmental goals.

In conclusion, zircon mullite bricks present a range of advantages that cater specifically to the demands of the glass industry. Their unique properties contribute to enhanced production efficiency, durability, and sustainability, making them a vital component in modern glass manufacturing. By incorporating these advanced refractory materials, companies can achieve both performance excellence and a competitive edge in the market.