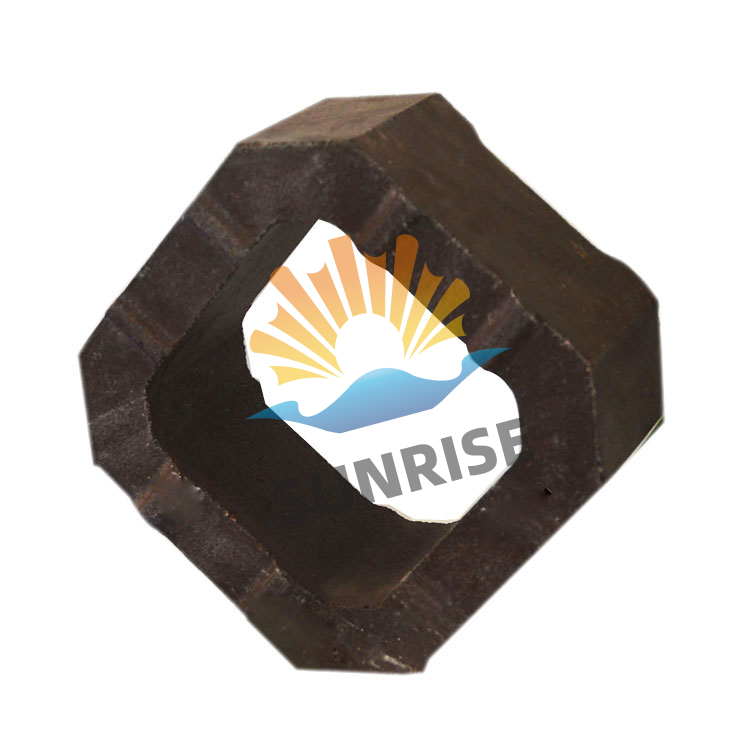

When it comes to refractory materials, the choice between ordinary magnesia-chrome bricks and magnesia bricks can significantly impact the overall performance of various applications. As a professional in the field, I aim to provide a comprehensive comparison of these two types of bricks, focusing on their performance characteristics that matter most in industrial applications.

Ordinary magnesia-chrome bricks are uniquely designed to offer enhanced thermal shock stability, which sets them apart from regular magnesia bricks. The ability to withstand rapid temperature fluctuations is crucial in high-temperature environments, such as those found in steelmaking and glass production. This characteristic ensures that ordinary magnesia-chrome bricks can maintain their structural integrity under extreme conditions.

In addition to thermal shock stability, ordinary magnesia-chrome bricks exhibit superior slag resistance. This attribute is pivotal in industries where exposure to molten slag is frequent. The advanced chemical composition of these bricks allows them to withstand slag penetration, significantly reducing wear and prolonging service life.

The analysis clearly indicates that for applications requiring high thermal shock stability and excellent slag resistance, ordinary magnesia-chrome bricks are the superior choice. Understanding these performance differences aids in making an informed decision, ultimately leading to enhanced operational efficiency and reduced maintenance costs. As we continue to explore advancements in refractory materials, the distinction between these brick types will remain critical for industry stakeholders.