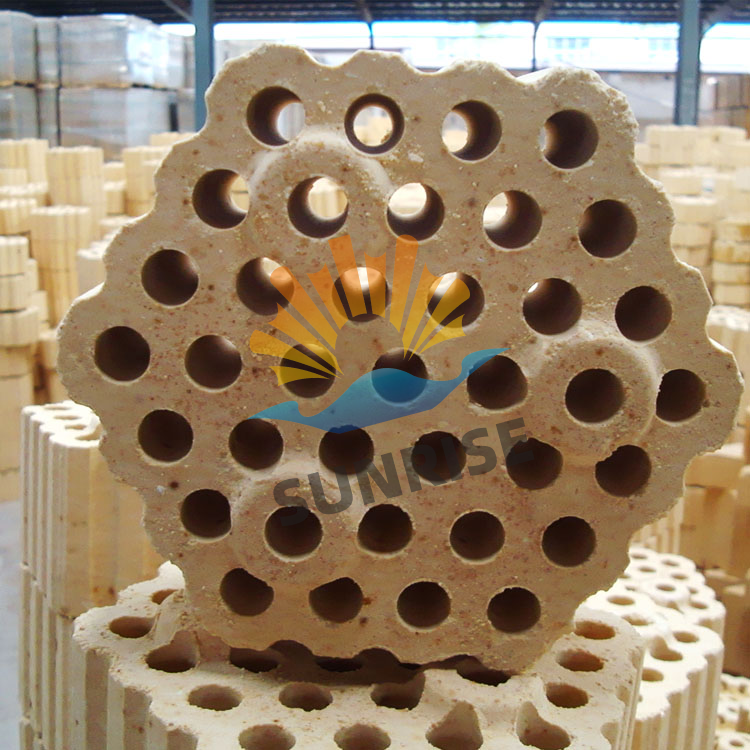

High-Quality Silica Bricks for Hot Blast Furnace Applications

2024-12-27

Zhengzhou Sunrise Refractory Co., Ltd.

Tutorial Guide

Discover the advantages of using high-quality silica bricks in hot blast furnace applications. Our silica bricks, with SiO2 content of 95% or higher, offer exceptional thermal stability, low thermal expansion, and high resistance to thermal shock, ensuring efficient and reliable operation in high-temperature industrial environments.

Introduction

Silica bricks have become the preferred choice for hot blast furnaces, gradually replacing traditional clay and high-alumina bricks. These high-purity bricks are engineered for optimal performance under extreme conditions, making them essential in modern industrial applications.

Key Features

- High Purity: SiO2 content of 95% or more for stable high-temperature performance.

- Excellent Thermal Conductivity: Supports efficient operation of hot blast furnaces.

- High-Temperature Resistance: Cold compressive strength of ≥45MPa to withstand harsh working environments.

- Low Thermal Expansion: Thermal expansion rate at 1000℃ ≤1.25%, ensuring structural stability.

- High Softening Point: Softening point at 0.2MPa ≥1650℃ suitable for high-temperature applications.

- Low Creep Rate: Reliable for long-term use with a creep rate of just 0.8% (0.2MPa×50h).

Applications

These silica bricks are ideally suited for:

- High-temperature zones in hot blast furnaces.

- Other industrial furnace equipment subjected to high temperature and pressure.

For more information or to request a quote, please feel free to contact us!