High-Performance Silica Bricks for Hot Blast Stoves - Superior Refractory Solutions

2024-12-04

Zhengzhou Sunrise Refractory Co., Ltd.

Share and exchange

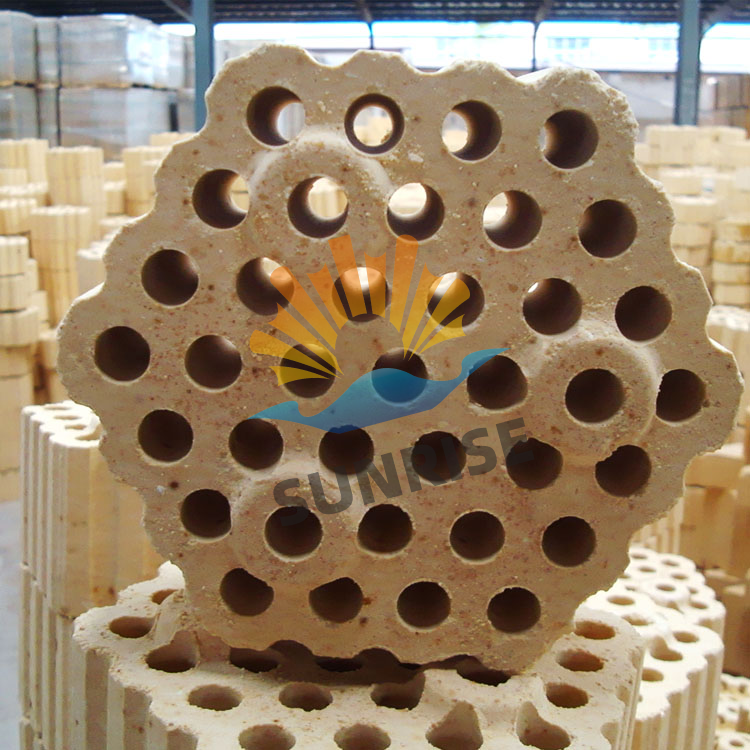

Discover our premium Hot Blast Stove Silica Bricks, designed for high-temperature applications. With a SiO2 content of ≥95%, excellent thermal conductivity, and low creep rates, our silica bricks ensure the efficient and reliable operation of your industrial furnaces.

Introduction

The Hot Blast Stove Silica Bricks are specially manufactured for high-temperature regions, replacing traditional clay and high-alumina bricks. With a predominantly flaky quartz composition, these bricks are the optimal solution for increasing blast furnace temperatures.

Advantages of Our Silica Bricks

- High Purity: SiO2 content of ≥95% ensures superior high-temperature performance.

- Excellent Thermal Conductivity: Enhances the operational efficiency of hot blast stoves.

- High-Temperature Resistance: Cold compressive strength of ≥45MPa suitable for extreme conditions.

- Low Expansion Rate: Thermal expansion ≤1.25% keeps the structure stable.

- High Softening Point: Load softening temperature of ≥1650℃ is ideal for high-temp operations.

- Low Creep Rates: Only 0.8% (0.2MPa × 50 hours) ensures durability.

Ideal Applications

Perfect for use in the high-temperature areas of hot blast stoves, our silica bricks are also suitable for other industrial furnaces operating under similar high-pressure conditions.

Conclusion

For those seeking reliability and performance in high-temperature refractory materials, our Hot Blast Stove Silica Bricks are the perfect choice. Contact us to learn more about how we can support your operational needs.