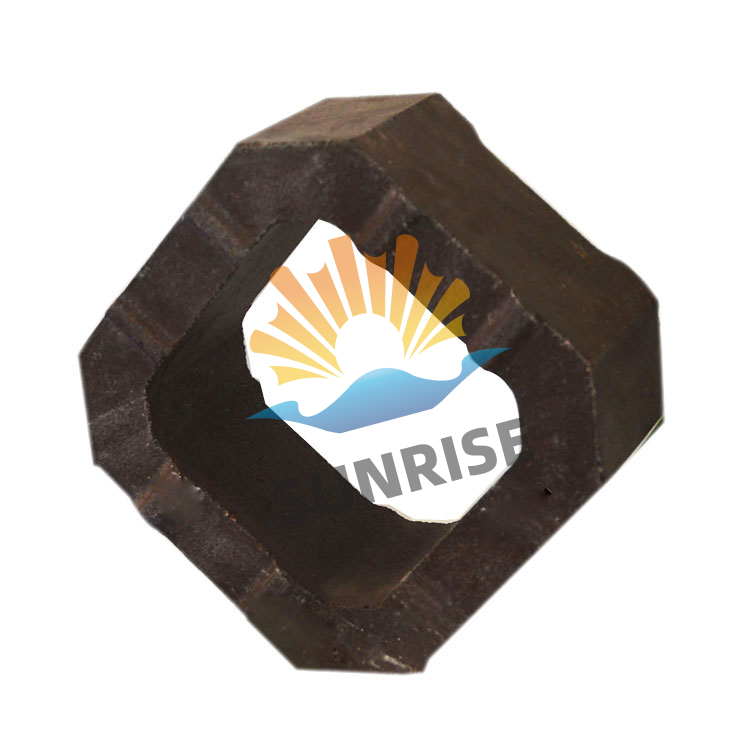

Magnesiochromite bricks, known for their excellent thermal stability and mechanical properties, are increasingly gaining traction in high-temperature applications across various industries. This article aims to explore the diverse applications of these bricks, analyze the changing market demand, and provide insights into future development trends.

1. Ceramic Industry: Magnesiochromite bricks are extensively used in kilns for the production of ceramics due to their ability to withstand extreme temperatures without degrading.

2. Steel Industry: In the steelmaking process, these bricks serve as linings for furnaces, protecting structural integrity while providing thermal insulation.

3. Cement Production: The cement sector relies on magnesiochromite bricks as they can endure the high thermal stress encountered during production.

The demand for magnesiochromite bricks has seen significant growth attributed to the expansion of industries requiring high-performance materials. Factors including technological advancements and the rise in industrial production rates have contributed to this trend. The global market is projected to expand further as manufacturers seek durable and reliable materials.

As industries evolve, the demand for advanced materials will increase. The future of magnesiochromite bricks seems promising with potential innovations in formulations that enhance performance in harsher environments. Additionally, sustainability trends in materials science may lead to the development of greener production methods for these bricks, resulting in broader market acceptance.

In conclusion, magnesiochromite bricks exhibit significant versatility across numerous high-temperature applications, backed by a robust market demand. By understanding the trends and evolving needs of various sectors, companies can leverage opportunities within this market to drive growth and innovation.