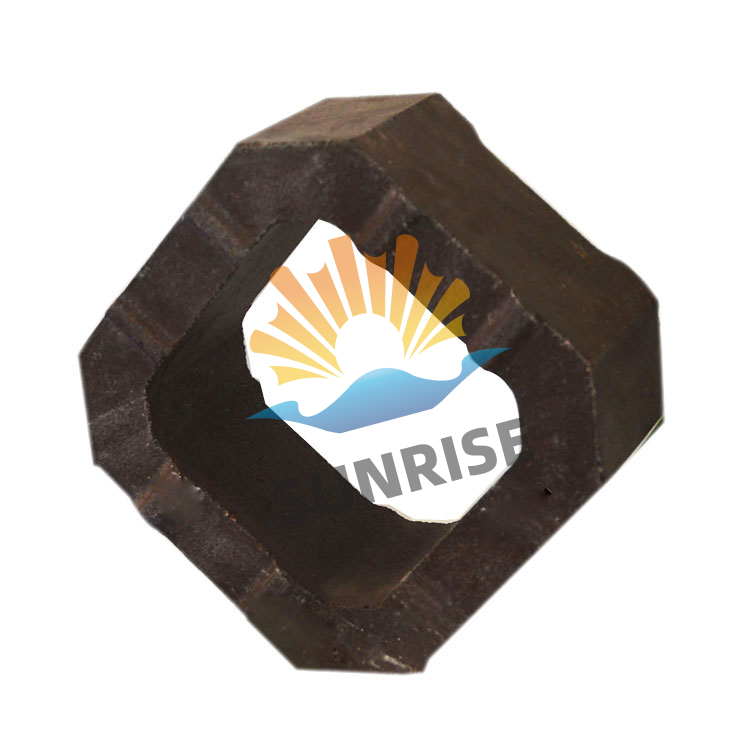

In the realm of high-temperature industrial applications, the selection of refractory materials plays a pivotal role in ensuring operational efficiency and durability. Ordinary magnesite-chromite bricks, known for their unique properties, have emerged as a preferred choice among engineers and industry experts. This article explores the distinctive characteristics of these bricks, emphasizing their exceptional physical and chemical performance and the immense value they offer in extreme conditions.

One of the standout traits of ordinary magnesite-chromite bricks is their high mechanical strength. These bricks exhibit remarkable resistance to wear and tear, making them suitable for industries where high abrasion is prevalent. The inherent density of these materials contributes to their durability, enabling them to withstand intense operational conditions without significant degradation.

The refractoriness of ordinary magnesite-chromite bricks is another critical advantage. Their ability to maintain structural integrity at elevated temperatures renders them highly effective in environments such as steel production and glass manufacturing. Unlike many other refractory options, these bricks can endure extreme thermal loads without experiencing significant thermal distortion.

Thermal shock stability is a defining factor in the performance of refractory materials. Ordinary magnesite-chromite bricks excel in this regard, exhibiting superior resistance to sudden temperature fluctuations. This characteristic is especially beneficial in processes that demand rapid heating and cooling, ensuring that the structural integrity of the material is upheld even under adverse conditions.

Additionally, these bricks demonstrate excellent chemical resistance, effectively withstanding the corrosive effects of various slag compositions and aggressive environments. This resilience to chemical attack not only enhances their longevity but also minimizes the frequency of maintenance interventions, thereby optimizing operational costs.

The impressive combination of high strength, refractoriness, and thermal shock stability renders ordinary magnesite-chromite bricks ideal for a range of high-temperature applications. Predominantly utilized in steelmaking furnaces, these bricks are also finding their way into non-ferrous metallurgy, cement industries, and other sectors where temperature extremes and physical demands are commonplace.

In summary, ordinary magnesite-chromite bricks present a formidable option in the landscape of high-strength refractory materials. Their unique physical and chemical properties not only enhance performance but also contribute significantly to the efficiency and reliability of high-temperature industrial processes. As industries evolve, the demand for durable and efficient materials like ordinary magnesite-chromite bricks is poised to grow, underscoring their indispensable role in modern manufacturing.