As the leader of our marketing team, I have the privilege of exploring various innovative materials that play a crucial role in the manufacturing processes across industries. One such material is zircon mullite bricks, known for their exceptional performance in high-temperature applications, particularly in the glass production sector.

Zircon mullite bricks exhibit outstanding thermal stability and mechanical strength, which are essential in environments that demand durability. Their low thermal conductivity aids in energy efficiency, reducing overall production costs. Additionally, these refractory materials offer excellent resistance to chemical corrosion, making them ideal for the aggressive conditions often encountered in glass manufacturing.

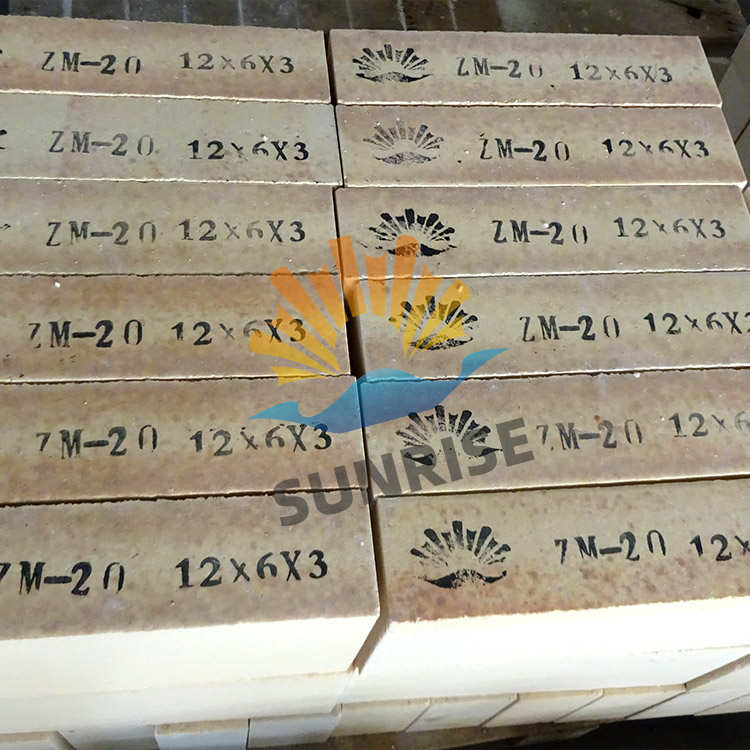

In the glass industry, zircon mullite bricks are widely used for lining furnaces, kilns, and other high-temperature equipment. They enhance operational efficiency by providing superior insulation and heat retention, leading to improved melting and processing of raw materials. Their robust nature ensures prolonged service life, minimizing downtime for repairs or replacements.

In conclusion, zircon mullite bricks stand out as a vital component in the glass production sector due to their remarkable properties and versatile applications. By investing in these high-quality refractory materials, manufacturers can achieve better product quality, reduced energy consumption, and enhanced operational durability, ultimately leading to sustainable growth and competitive advantages in the market.