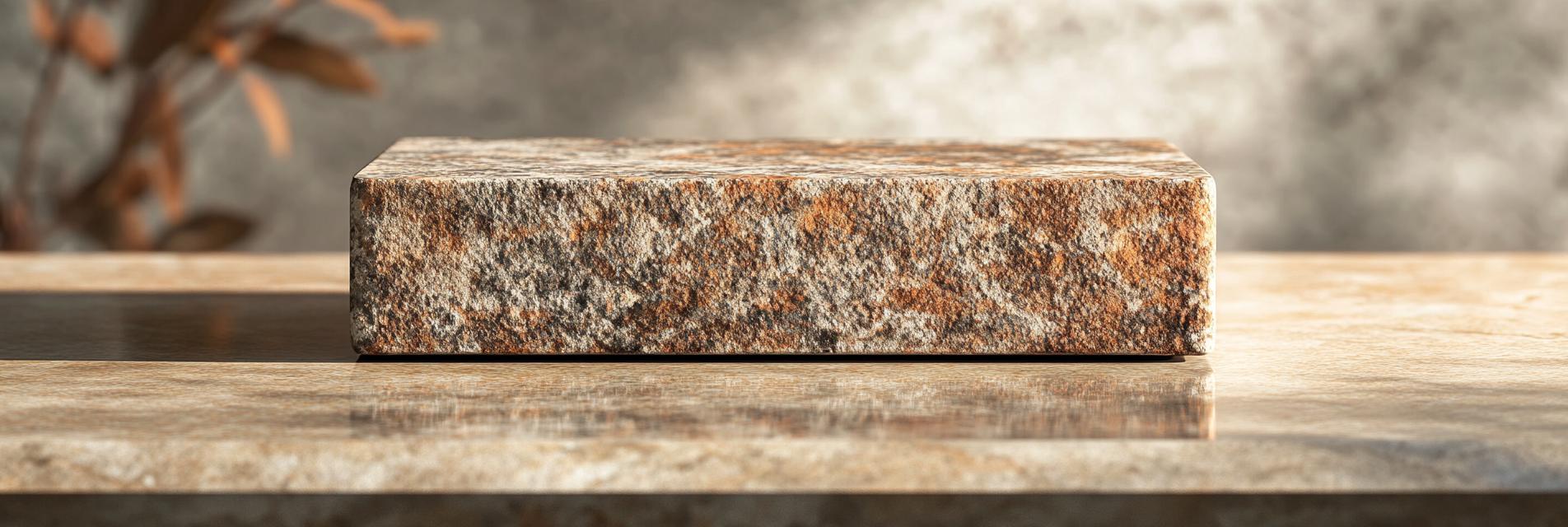

Mullite-zirconia bricks have garnered significant attention in various high-temperature industrial applications due to their exceptional durability. Their ability to withstand extreme thermal and chemical conditions has made them a preferred choice in industries such as metallurgy, ceramics, and petrochemicals.

The remarkable durability of mullite-zirconia bricks is attributed to their unique microstructure, which combines the strength of mullite and the thermal stability of zirconia. This synergy results in a material that not only exhibits high resistance to thermal shock but also maintains structural integrity under prolonged exposure to high temperatures.

One of the key advantages of these bricks is their low thermal conductivity, which minimizes heat loss and enhances energy efficiency in industrial applications. Additionally, their superior resistance to chemical corrosion allows them to perform effectively in environments that would degrade other materials.

Mullite-zirconia bricks are specifically engineered to endure harsh operating conditions. Their performance is particularly noteworthy in furnaces and kilns, where consistent thermal and mechanical stress can lead to structural failures. The thermal expansion characteristics of these bricks are closely aligned with metals and other materials commonly used in such high-stress environments, thereby reducing the risk of cracking and spalling.

In addition, the ability of mullite-zirconia bricks to retain strength at elevated temperatures ensures that they can support the demanding workloads encountered in heavy industrial applications. Their fatigue resistance contributes significantly to minimizing maintenance costs and downtime, making them a cost-effective choice in the long term.

The versatility of mullite-zirconia bricks extends to various sectors. For instance, in the metal processing industry, their ability to withstand slag penetration and erosion enhances the operational life of furnaces. Similarly, in the ceramic industry, their stability and resistance to deformative stress allow for more efficient firing processes.

Looking ahead, ongoing research and development in the composites realm may lead to even more advanced formulations of mullite-zirconia materials, potentially opening new avenues for higher efficiency and performance in exceptionally challenging environments.

In summary, the durability of mullite-zirconia bricks makes them an indispensable material in high-temperature applications. Their unique properties not only enhance their longevity but also provide significant operational advantages to industries reliant on heat-resistant materials. Understanding and leveraging these qualities will be crucial for future advancements in material science and industrial efficiency.