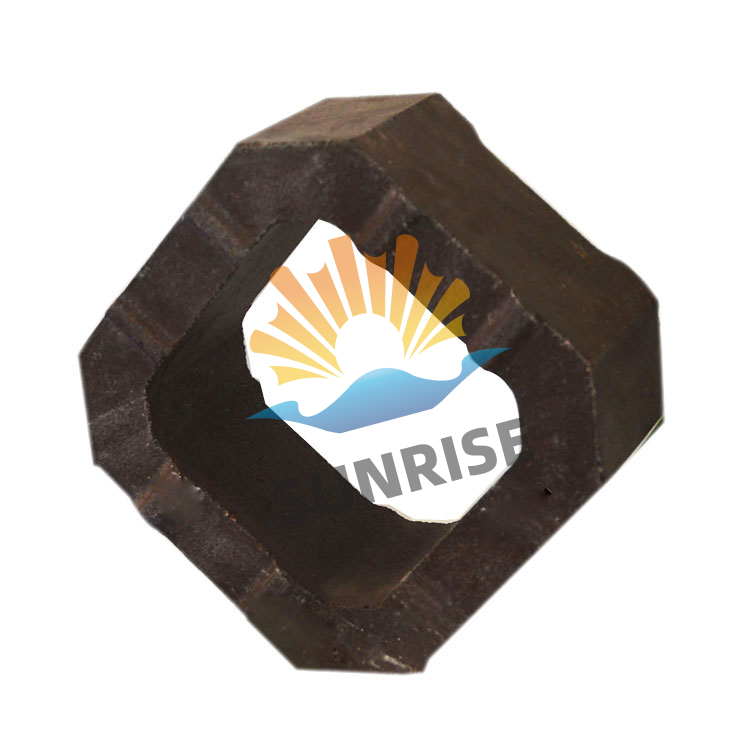

In the realm of high-strength refractory materials, common magnesia-chrome bricks stand out due to their remarkable properties. These bricks are specifically designed to withstand extreme temperatures, making them invaluable in various industrial applications. This article delves into the unique characteristics that contribute to their widespread use in high-temperature environments.

Common magnesia-chrome bricks are known for their high durability, excellent thermal stability, and impressive resistance to corrosion. Their physical properties, including density and thermal conductivity, are optimized for situations where heat management is crucial. Additionally, the chemical resistance provided by chrome oxide in combination with magnesium oxide enhances their performance in aggressive environments.

One of the standout features of magnesia-chrome bricks is their superior refractory properties. These bricks are capable of withstanding high temperatures without melting or deforming, making them ideal for applications in steelmaking, cement kilns, and other high-temperature processes. The ability to maintain structural integrity under extreme conditions is a key advantage that sets them apart from other refractory materials.

Thermal shock stability is another critical factor that contributes to the effectiveness of common magnesia-chrome bricks. They exhibit minimal expansion and contraction when exposed to rapid temperature changes, reducing the risk of cracking or failure during abrupt thermal fluctuations. This property is particularly beneficial in industrial applications where constant temperature variations occur.

In conclusion, common magnesia-chrome bricks are an exceptional choice for high-temperature applications due to their outstanding physical and chemical properties, refractory capabilities, and thermal shock stability. Investing in these high-strength refractory materials can lead to enhanced operational efficiency and reduced maintenance costs in challenging industrial environments.